Specialty Products Inc. had experienced some difficulties with the LOCK n’ LOAD Gun Blocks’ nucleation “Air Port” building up with Spray Foam material due to back pressure. While at job sites and/ or with our in-house projects, applicators have had trouble fully cleaning out this port. The interior portion of this nucleation “Air Port” is “stepped”. This was causing the material inside to have a mushroom type shape, building up with product, and not allowing the product to be completely removed.

We had previously used the Pin-Vise with a 1/8” bit provided in the LOCK n’ LOAD Gun Box Kit to do the clean outs in that port. Applicators using spraying foams, had been inserting the clean out tool into the front and the back of the gun, thinking that the nucleation “Air Port” was cleaned out. That was not the case. The foam was collapsing after the removal of the bit (known as the marshmallow effect), and still causing restriction in air pressure.

To alleviate this problem and make the “clean outs” easier, we have placed an 18-8 Stainless Steel “sleeve” inside of this port to create the same size cylinder shape completely throughout the block. This will eliminate the possibilities of

product staying within the block. There are spare “sleeves” provided in the updated LOCK n’ LOAD Gun Box Kits. Also, the drill bit length is now longer and increased in diameter slightly to help with the clean out procedure. These items can be purchased at our Parts Departments.

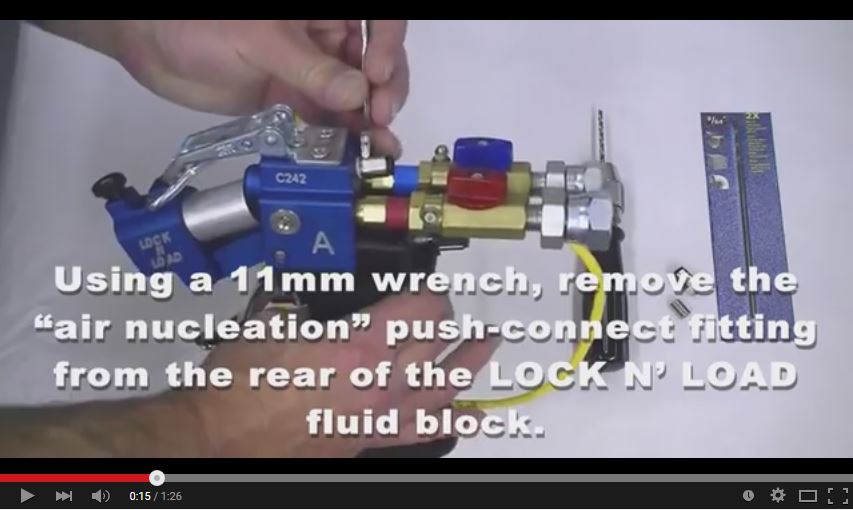

Watch a demonstration here:

https://www.youtube.com/watch?v=5BmrOB2pHlg